CWI PART B 쉽게 공부하는법 - 4. Pressure Piping

목차

CWI Part B의 4장은 Pressure Piping 입니다. 압력배관이라는 뜻인데요. 일반 배관과 다른 점이 있으니, Pipeline과 다른 기준이 적용되겠죠? 이번에도 당연히 시험에 나올 부분만 딱 짚어놨으니, 해당 부분을 중점적으로 보시되, 언급하지 않은 부분은 생략하기 보단 그래도 내용은 알고 계시는 것이 좋을 것입니다. 다만, 제가 남겨놓은 부분에 대해서는 완벽하게 숙지하고, 가장 좋은 것은 암기하는 것이지만, 암기를 못하시겠다면 적어도 어느 위치에 있는지 정도는 꼭 익혀두시고 시험장에 가시기 바랍니다. 아래에는 그동안 작성되었던 CWI Part B 쉽게 공부하는법에 대해 링크를 남겨두었으니 참고하시기 바랍니다.

CWI PART B 쉽게 공부 하는 법 : 시험에 나올 것만 보자.

CWI PART B 쉽게 공부 하는 법 : 시험에 나올 것만 보자.

CWI 합격 후기를 남긴 후, 곧 이어 바로 시험 공부하는 법을 포스팅 하는 것은, 앞으로 쉴 수 있는 날이 얼마 남지 않았기도 하고, 이제 API 시험 공부를 시작하여야 하기 때문입니다. 당장 9월에 API

whiteheadyouth.tistory.com

CWI PART B 쉽게 공부하는법 - 2. Structural steel

CWI PART B 쉽게 공부하는법 - 2. Structural steel

API510 시험이 코 앞이라, 510 공부를 하면서 관련 포스팅을 하느랴 CWI 포스팅에 소홀했었습니다. 생각보다 많은 분들이 본 블로그에 찾아주셨고, 많은 분들의 요청에 따라 CWI 포스팅을 하나씩 진

whiteheadyouth.tistory.com

CWI PART B 쉽게 공부하는법 - 3. Pipeline

CWI PART B 쉽게 공부하는법 - 3. Pipeline

CWI PART B 쉽게 공부하는 법 세번째 시간입니다. 3장은 Pipeline으로 3장의 시방서는 api1104 코드 및 ASME Sec IX, ASME B 31.3을 바탕으로 만들어졌다고 합니다. 이 시방서를 바탕으로 Pipe 시편의 합/불여부

whiteheadyouth.tistory.com

4.1.1 The internal misalignment of the ends to be joined shall not be greater than 2 mm. When the internal misalignment exceeds the allowable, it is preferred that the component with the wall extending internally be internally trimmed. However, trimming shall result in a piping component thickness not less than the minimum allowable thickness, and the change in contour shall not exceed 30 degrees.

4.1.5 After welding commences, the minimum preheat temperature should be maintained until the joint is completed. However, welding may be interrupted and the joint allowed to cool slowly provided a minimum 10 mm thickness of weld is deposited or 25% of the groove is filled, whichever is less.

4.1.6 Arc strikes outside the area of the intended weld are unacceptable.

4.1.7 As-welded surfaces, including tie-ins, shall be smooth, uniform, and free from overlap.

4.1.8 Base metal surfaces shall be free of spatter.

4.1.9 Repair Welding. Any discontinuities in excess of the maximum permitted in 4.2 shall be removed and may be repaired by welding after the area has been magnetic particle or dye penetrant inspected to assure complete removal of discontinuities.

4.1.9.1 Defect Removal. All defects in welds or base materials requiring repair shall be removed by flame or arc gouging, grinding, chipping, or machining. Preheating may be required for flame or arc gouging on certain alloy materials of the air hardening type in order to prevent surface checking or cracking adjacent to the flame or arc gouged surface. When a defect is removed but welding repair is unnecessary, the surface shall be contoured to eliminate any sharp notches or corners. The contoured surface shall be reinspected by the same means originally used for locating the defect.

4.1.9.2 Repair Welds. Repair welds shall be made in accordance with a WPS using qualified welders, recognizing that the cavity to be repair welded may differ in contour and dimension from a normal joint preparation and may present different restraint conditions. All repair welds shall meet the visual acceptance criteria of 4.2.

4.1.9.3 Inspection. All weld repairs of depth exceeding 25 mm or 20% of the section thickness, whichever is the lesser (as measured from the pipe surface), shall be inspected by radiography and by magnetic particle or dye penetrant inspection of the finished weld surface. All weld repairs of depth less than 20% of the section thickness, or 25 mm, whichever is the lesser shall be examined by magnetic particle or dye penetrant inspection of the first layer of each 6 mm thickness of deposited weld metal, and of the finished weld surface. Magnetic particle or dye penetrant testing of the finished weld surface shall be done after postweld heat treatment.

4.2 Visual Inspection Acceptance Criteria. Any of the following indications are unacceptable:

4.2.1 Cracks

4.2.2 Undercut that is greater than 0.8 mm deep. This also includes any other reduction of base metal at the weld toes.

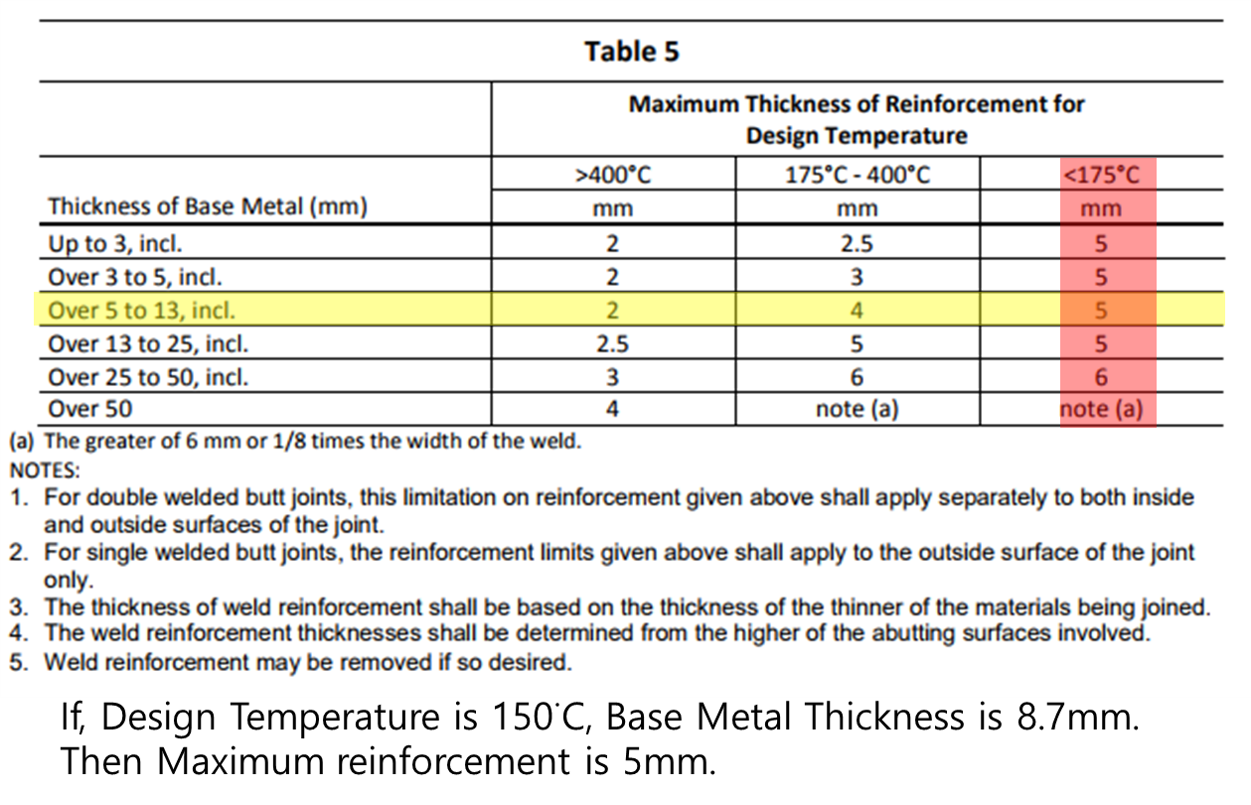

4.2.3 Weld reinforcement greater than specified in Table 5

4.2.4 Lack of fusion

4.2.5 Incomplete penetration

4.2.6 Any other linear indications greater than 5 mm long

4.2.7 Surface porosity with rounded indications having dimensions greater than 5 mm or four or more rounded indications separated by 2 mm or less edge to edge in any direction. Rounded indications are indications that are circular or elliptical with their length less than three times their width.

취업에 큰 도움이 되는 자격증 (CWI, API, NEBOSH)

취업에 큰 도움이 되는 자격증 (CWI, API, NEBOSH)

요즘은... 요새 취업을 준비하는 많은 취준생들은 기본적으로 일명 쌍기사라고 불리는, 기사 자격증 2개, 컴활, 한국사능력검정, 어학점수, 대외활동, 인턴십등의 어마어마한 스펙들을 자랑하고

whiteheadyouth.tistory.com

CWI(국제용접검사관) 두달 공부해서 한번에 합격한 후기

CWI(국제용접검사관) 두달 공부해서 한번에 합격한 후기

CWI-국제용접검사관 : 반드시 취득해야할 자격증 CWI가 무엇인가요? 건설현장이든, 혹은 일반 생산 현장이든 용접 작업이 있는 곳에 반드시 필요한 것이 WPS, PQR, WPQ이고, 이것을 활용, 용접 품질을

whiteheadyouth.tistory.com

최신 국제 인스펙터 자격증 정보를 실시간 업데이트 받고 싶으신 분은 아래의 플러스 친구를 추가하시면 추가 되는 모든 정보를 쉽게 받아보실 수 있습니다.

☞ 플러스친구 추가 바로 가기는 아래의 링크를 눌러주세요!

☞ http://pf.kakao.com/_xfqxjks

White INSPECTION

국제 인스펙터 자격증 취득 정보 CWI, API, NACE, ASNT, NEBOSH 등 공부자료

pf.kakao.com